An Analysis of Steel Material Inventory Management Using the Just-in-Time (JIT) Approach: A Case Study at PT XYZ

Main Article Content

Abstract

This study investigates the problem of excessive raw material inventory at PT XYZ, driven by a misalignment between procurement planning and actual production demand, which has led to higher storage costs and operational inefficiencies. The research aims to analyze the root causes of inventory control issues and design an optimized inventory management system using the Just-In-Time (JIT) approach. A qualitative methodology with a social situation framework was applied, incorporating direct observations, in-depth interviews with warehouse managers and staff, and secondary document analysis. Triangulation techniques were used to ensure data credibility and reliability. Findings indicate that JIT implementation reduces inventory excess, optimizes storage utilization, strengthens coordination between departments and suppliers, lowers unnecessary costs, and improves service quality. The study contributes to the understanding of JIT application in the automotive industry, with novelty demonstrated through PT XYZ’s shift from traditional inventory methods to JIT. The research concludes that JIT is an effective solution for addressing inventory control challenges and suggests that its adoption could serve as a model for other manufacturing firms seeking to enhance inventory efficiency and competitiveness.

Downloads

Article Details

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

References

Aprila, D., Andriani, W., & Ananto, R. P. (2023). Financial Management of Nagari Owned Enterprises (BUMNAG) and Its Impact on Community Welfare. Jurnal Akuntansi Bisnis, 16(2), 210–225. https://doi.org/10.30813/jab.v16i2.4461

Capkun, V., Hameri, A.-P., & Weiss, L. A. (2009). On the relationship between inventory and financial performance in manufacturing companies. International Journal of Operations & Production Management, 29(8), 789–806. https://doi.org/10.1108/01443570910977698

Chira, R., & Muşetescu, A. (2017). The Importance Of Integrated Logistics. Knowledge Horizons : Economics, 9(2), 72–79.

Cuatrecasas-Arbós, L., Fortuny-Santos, J., Ruiz-de-Arbulo-López, P., & Vintró-Sanchez, C. (2015). Monitoring processes through inventory and manufacturing lead time. Industrial Management + Data Systems, 115(5), 951–970.

Hamal, V., Patel, S., Vyas, H., & Bhuria, S. (2024). Study of Implementation of Just in Time Inventory Management Technique in Manufacturing Industry. International Journal of Creative Research Thoughts, 12(3), 509–526. https://doi.org/10.8503/IJCRT.484vu484.123

Heitasari, D. N., Pratama, I. L., & Revalina, F. A. (2025). Vendor Management Model to Achieve Just In Time ( JIT ) in Material Procurement. Journal of Applied Sciences, Management and Engineering Technology, 6(1), 25–31. https://doi.org/10.31284/j.jasmet.2025.v6i1.6821

Kelkar, A. S. (1999). A JIT implementation using hybrid KANBAN-CONWIP modeling approach. ProQuest Dissertations & Theses.

Khoza, S., Mafini, C., & Loury Okoumba, W. V. (2022). Lean practices and supply-chain competitiveness in the steel industry in Gauteng, South Africa. South African Journal of Economic and Management Sciences, 25(1), 1–14.

Kim, G. C., & Takeda, E. (1996). The JIT philosophy is the culture in Japan. Production and Inventory Management Journal, 37(1), 47.

Kumar, P., & Sasirekha, S. (2024). A Study on inventory management in a steel industry. International Journal of Research Publication and Reviews, 5(4), 8883–8890. https://doi.org/10.2139/ssrn.4909110

Madanhire, I., & Mbohwa, C. (2016). Application of just in time as a total quality management tool: the case of an aluminium foundry manufacturing. Total Quality Management & Business Excellence, 27(1–2), 184–197. https://doi.org/10.1080/14783363.2014.969909

Quan, B., Li, S., & Wu, K.-J. (2022). Optimizing the Vehicle Scheduling Problem for Just-in-Time Delivery Considering Carbon Emissions and Atmospheric Particulate Matter. Sustainability, 14(10), 6181.

Ratnamurni, E. D., Ludiya, E., & Luthfiartie, A. (2022). Quality Risk Management in Infusation Product Distribution Using Failure Mode and Effect Analysis (FMEA) and Analytical Hierarchy Process (AHP) Methods. International Journal of Science, Technology & Management, 3(1), 229–244. https://doi.org/10.46729/ijstm.v3i1.429

Roy, R. N. (2020). Implementing just-in-time-based supply chain for the bulk items in an integrated steel plant. International Journal of Intelligent Enterprise, 7(4), 405–422. https://doi.org/10.1504/IJIE.2020.110762

Sebtaoui, F. E., Adri, A., & Rifai, S. (2020). Literature review on successful JIT implementation: benefits, obstacles and critical success factors. International Journal of Logistics Systems and Management, 37(2), 153–172. https://doi.org/10.1504/IJLSM.2020.110571

Singh, J., Singh, H., & Singh, G. (2018). Productivity improvement using lean manufacturing in manufacturing industry of Northern India. International Journal of Productivity and Performance Management, 67(8), 1394–1415.

Suci Nurrohimmah, M., Ludiya, E., & Dwiana Ratnamurni, E. (2023). Analysis Of Perfume Seed Inventory Control At PT. Perintis Kiprah Sampono (Case Study Of Aromania Perfumery Karawang). International Journal of Science, Technology & Management, 4(1), 175–181. https://doi.org/10.46729/ijstm.v4i1.711

Suflani, S., Khaeruman, K., & Jawahir, M. M. (2023). Inventory Management Analysis Using the Material Requirement Planning (Mrp) Method in the Optimization of Handicraft Raw Materials. International Journal of Multidisciplinary Research and Literature, 2(3), 359–368. https://doi.org/10.53067/ijomral.v2i3.124

Sugiyono. (2024). Metode Penelitian Kuantitati, Kualitatif dan R&D. Bandung: Alfabeta.

Truong, K. D. (2023). Impact Of Inventory Management On Firm Performance a Case Study Of Listed Manufacturing Firms On Hose. International Journal of Information, Business and Management, 15(1), 93–115.

Vamsi Krishna Jasti, N., & Kodali, R. (2014). A literature review of empirical research methodology in lean manufacturing. International Journal of Operations & Production Management, 34(8), 1080–1122. https://doi.org/10.1108/IJOPM-04-2012-0169

Wafa, M. A., & Yasin, M. M. (1998). A conceptual framework for effective implementation of JIT: An empirical investigation. International Journal of Operations & Production Management, 18(11), 1111–1124.

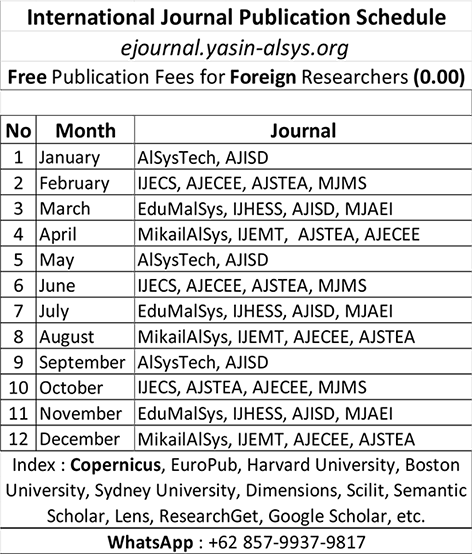

Find the perfect home for your research! If this journal isn't the right fit, don't worry—we offer a wide range of journals covering diverse fields of study. Explore our other journals to discover the ideal platform for your work and maximize its impact. Browse now and take the next step in publishing your research:

| HOME | Yasin | AlSys | Anwarul | Masaliq | Arzusin | Tsaqofah | Ahkam | AlDyas | Mikailalsys | Edumalsys | Alsystech | AJSTEA | AJECEE | AJISD | IJHESS | IJEMT | IJECS | MJMS | MJAEI | AMJSAI | AJBMBR | AJSTM | AJCMPR | AJMSPHR | KIJST | KIJEIT | KIJAHRS |