A Systematic Review of Seven Core Quality Control Tools and Their Applications in Manufacturing Process Improvement

Main Article Content

Abstract

This paper provides a comprehensive analysis of the seven basic quality control tools and their applications in addressing problems within manufacturing industries. The tools examined include cause-and-effect diagrams, check sheets, control charts, histograms, Pareto charts, scatter diagrams, and flowcharts. Each tool is discussed in detail, focusing on its purpose, theoretical foundations, and practical applications in quality management. The study emphasizes how these tools support systematic identification, analysis, and resolution of production challenges, thereby improving process efficiency, reducing defects, and enhancing overall product quality. By demonstrating their versatility and effectiveness, the paper highlights the relevance of these tools as essential components of continuous improvement strategies in modern manufacturing.

Downloads

Article Details

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

References

American Society for Quality. (2024). Cause and effect diagram. Retrieved August 14, 2025, from https://asq.org/quality-resources/fishbone

Al-Hadeethi, H. M. (2015). Application of Pareto diagram in process control. Journal of Quality and Process Improvement, 8(2), 45–52.

Ayenigba, A.A. and Ajao, O. M. Application of Statistical Quality Control in Monitoring the Production and Marketing Processof Sachet Water at Ajayi Crowther Water Factory, Oyo, Nigeria. Ajayi Crowther J. Pure Appl. Sci. 2024, 4(1), pp. 25-36. | doi:https://doi.org/10.56534/acjpas.2025.04.01.25

Ayenigba, A. A. (2025). Statistical Quality Control as a Tool for Monitoring and Improving Dimensional Accuracy in Soap Manufacturing. Mikailalsys Journal of Mathematics and Statistics, 3(3), 619-631. https://doi.org/10.58578/mjms.v3i3.6431

Bambharoliya, T. R. (2015). Using quality tools to reduce product rejection rates in a small manufacturing company. Journal of Manufacturing Processes, 20(3), 45-50.

Besterfield, D. H. (2013). Quality control (8th ed.). Pearson Education.

Domtar. (2021). 8 Steps of the Paper Making Process. Retrieved from https://www.domtar.com/blog-posts/8-steps-of-the-paper-making-process/

Chaudhuri, P., Das, S., and Roy, A. (2019). Application of histograms for data analysis in manufacturing processes. International Journal of Advanced Manufacturing Technology, 104(5), 1237-1245.

DeVor, R. E. (2017). Statistical quality design and control. Prentice Hall.

Frayman, H. (2002). Foundations of quality management: Concepts and applications. Wiley.

Grima, P., García-Díez, S., and Tort-Martorell, X. (2021). Use of Ishikawa diagrams in defect analysis of circuit board assemblies. Quality Engineering, 33(1), 1-11.

Hu, Z., Li, Y., and Wang, J. (2020). Control charts in service quality monitoring: A case study. Service Science, 12(2), 87-95.

Ishikawa, K. (1990). Introduction to quality control. Productivity Press.

Jones, A. B. (2000). Analysis of defective values in manufacturing processes: A case study on p-chart construction. Journal of Statistical Process Control, 15(3), 429–432.

Montgomery, D. C. (2017). Introduction to statistical quality control (8th ed.). Wiley.

Muhammad, I. (2015). DMAIC framework implementation in fan production: A case study using Ishikawa's tools. Industrial Engineering Journal, 47(4), 30-37.

Mukherjee, P. N. (2012). Total quality management. PHI Learning Pvt. Ltd.

Soković, M., Pavletić, D., and Krulcic, E. (2018). Pareto analysis for problem-solving in quality improvement. Journal of Industrial Engineering and Management, 11(1), 34-46.

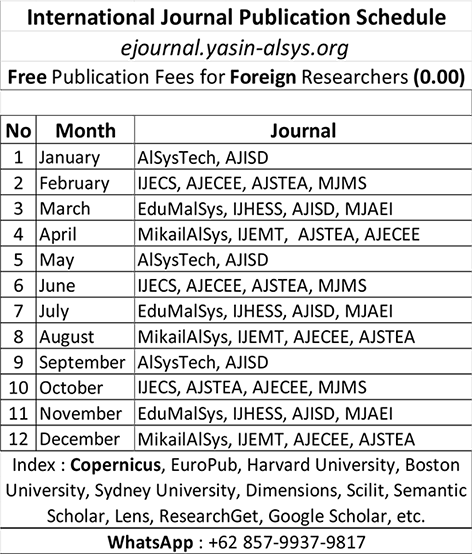

Find the perfect home for your research! If this journal isn't the right fit, don't worry—we offer a wide range of journals covering diverse fields of study. Explore our other journals to discover the ideal platform for your work and maximize its impact. Browse now and take the next step in publishing your research:

| HOME | Yasin | AlSys | Anwarul | Masaliq | Arzusin | Tsaqofah | Ahkam | AlDyas | Mikailalsys | Edumalsys | Alsystech | AJSTEA | AJECEE | AJISD | IJHESS | IJEMT | IJECS | MJMS | MJAEI | AMJSAI | AJBMBR | AJSTM | AJCMPR | AJMSPHR | KIJST | KIJEIT | KIJAHRS |