Perancangan Mata Pisau pada Traktor Pemanen Jagung Menggunakan Solidwork

Digital Object Identifier:

10.58578/ajstea.v1i1.1899

Digital Object Identifier:

10.58578/ajstea.v1i1.1899

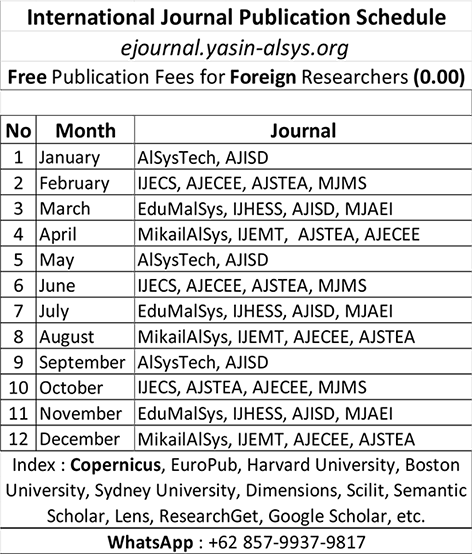

Please do not hesitate to contact us if you would like to obtain more information about the submission process or if you have further questions.

Abstract

Corn is one of the plants in agriculture that is needed in the lives of people in West Sumatra. Based on data in 2020 the need for corn is in the range of 1.2 million tons. But what can be produced is 939,466 tons. Traditional corn harvesting technology is a problem that causes corn production is not maximized. Corn harvesting tractor is one of the innovations in agricultural technology. The most important unit of the harvesting machine is the blade. The success of the machine in the harvesting process is determined by the shape and strength of the blade. Experimental testing is expensive and time consuming. Therefore, this study examines the design and simulation of blade strength on corn harvesting tractors with Solidwork software. The simulation carried out is a static analytic structural simulation. The simulation results include von-mises stress, displacement and factor of safety. Stress on the crossbar design has a maximum value of 2.168e+07 N/m^2 at the shaft connection and the inside of the bearing, maximum displacement on the side of the blade tip with a value of 1.953e-01 mm and FoS with a value of 5.553e+04. In design S the maximum stress is 2.476e+07 N/m^2, the displacement on the side of the blade tip is 2.199e-01 mm and the FoS is 1.052e+04. Both designs were given the same material AISI 1045, a force load of 87.05 N and a torque load of 41.5 Nm. The design that is suitable for use is the S shape design based on the results of the simulation and the shape that is more suitable for the harvesting process.

Downloads

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

References

Bairán, J. M., Tošic, N., & de la Fuente, A. (2021). Reliability-based assessment of the partial factor for shear design of fibre reinforced concrete members without shear reinforcement. Materials and Structures/Materiaux et Constructions, 54(5), 1–16. https://doi.org/10.1617/s11527-021-01773-z

Chang, K.-H. (2015). Solid Modeling. E-Design, 125–167. https://doi.org/10.1016/B978-0- 12382038-9.00003-X

C. P. I. Suseno, (2017). Analisa Distribusi Tegangan Sistem Sambungan Pada Knock Down River Ferry. Institut Teknologi Sepuluuh Nopember, 2017.

D. P. B. Kosasih, (2012). Teori dan Aplikasi Metode Elemen Hingga. Yogyakarta: Andi Yogyakarta, 2012.

I. N. Agus Adi, K. R. Dantes, and I. N. P. Nugraha, (2018). Analisis Tegangan Statik Pada Rancangan Frame Mobil Listrik Ganesha Sakti (Gaski) Menggunakan Software 2014. J. Pendidik. Tek. Mesin Undiksha, vol. 6, no. 2, p.113,2018,doi: 10.23887/jjtm.v6i2.13046.

Kemdikbud RI.(2015). MODUL DIKLAT PKB GURU ALAT MESIN PERTANIAN ALAT MESIN BUDIDAYA TANAMAN GRADE 6, 1-154. https://repositori.kemdikbud.go.id/17518/1/Modul%20PKB%20AlsintanAlat%2 0Mesin%20B udidaya.pdf,

Mulyana, T., Sebayang, D., Rafsanjani, A. M. D., Adani, J. H. D., & Muhyiddin, Y. S. (2017). Mesh control information of windmill designed by Solidwork program. IOP ConferenceSeries:MaterialsScienceandEngineering,277(1),012010.https://doi.org/10.1088/17 5789 9X/277/1/012010

P, Jamaluddin., Syam, H., Lestari, N., & Rizal, M. (2019). ALAT DAN MESIN PERTANIAN. Badan Penerbit Universitas Negeri Makassar.

Prasetyo, Eko, et al. (2020). Analisis Kekuatan Rangka Pada Mesin Transverse Ducting Flange (TDF) Menggunakan Software Solidworks. Rekayasa, 2020, 13.3: 299-306

Wicaksono., Banyuaji. (2018). Pengukuran Karakteristik Fisik dan Mekanik Tanaman Jagung sebagai Data Referensi untuk Perancangan Mesin Panen Jagung. Bogor Agricultural University (IPB).