Rancang Bangun dan Analisis Rangka Traktor Pemanen Jagung

Digital Object Identifier:

10.58578/ajstea.v1i1.1870

Digital Object Identifier:

10.58578/ajstea.v1i1.1870

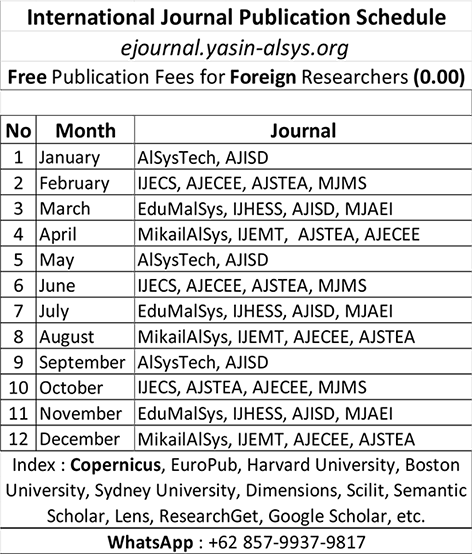

Please do not hesitate to contact us if you would like to obtain more information about the submission process or if you have further questions.

Abstract

A corn harvesting tractor is a tractor that operates using a diesel-powered engine which is used to harvest corn and is operated by humans. It is estimated that the presence of this tractor will lighten the burden on corn farmers who previously harvested using human power. Apart from making harvesting easier, corn harvesting tractors also increase production yields. This research aims to reveal the stress values that occur in the frame and the safety values from the results of the design of the tractor frame structure in the form of design and structural strength analysis. This research was limited to a loading of 200 kg. This research examines the design, simulation, and stress analysis of the frame structure of a 200 kg corn harvester tractor using the finite element method or can be said to be Finite Element analysis (FEA). ASTM A36 Steel material is used. Finite element analysis is carried out with a numerical system using software Solidworks 2020. The results of the simulation and analysis show that the tractor frame structure has a stress, deformation, and safety factor of 1.228e+07 N/m2, 2.934e-04 m, and 20.

Downloads

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

References

Ari, L., & Wibawa, N. (2019b). Kekuatan Rangka Main Landing Gear Untuk Pesawat UAV. V(1), 46–50

Hendrawan, M. A., Purboputro, P. I., Saputro, M. A., & Setiyadi, W. (2018). Perancangan Chassis Mobil Listrik Prototype "Ababil" dan Simulasi Pembebanan Statik dengan Menggunakan Premium 2016. The 7th University Research Colloquium 2018 STIKES PKU Muhammadiyah Surakarta, 96-105.

Imam sungkono, hery irawan, desmas arifianto patriwan, (2019), analisis desain rangka dan penggerak alat pembuat adonan kosmetik sistem putaran eksentrik menggunakan solidwork.

K. A. Nelson. (2018). Aplikasi Hasil Rancang Bangun CNC Router 3 Axis Terhadap Proses Kalibrasi Sumbu Z,” no. Politeknik Negeri Sriwijaya,.

Marlia Adriana , Anggun Angkasa B.P , & Masrianor. (2017). RANCANG BANGUN RANGKA (CHASIS) MOBIL LISTRIK RODA TIGA KAPASITAS SATU ORANG. Jurnal POLITEKNIK NEGERI TANAH LAUT

Mohamad Faizal H & Syahrul Umam. (2018). Analisis Kekuatan Dan Kualitas Sambungan Las Dengan Variasi Pendinginan Oli Dan Udara Pada Material Astm A36 Dengan Pengujian Ndt. Fakultas Teknologi Industri, Institut Sains dan Teknologi Nasional, Jakarta

Prasetyo, Eko, et al. (2020). Analisis Kekuatan Rangka Pada Mesin Transverse Ducting Flange (TDF) Menggunakan Software Solidworks. Rekayasa, 13.3: 299-306

Roswandi, I., Kawasan, G., Serpong, P., & Selatan, T. (2020). Analisis Beban Pada Hook Pembalik Produk Aeet Dengan Software Solidwork 17, 10–18.

S. Mubarok. (2019). Pengaruh Variasi Material Dan Beban Keamanan Pada Desain P Encakar Inner Puller Bearing Berbasis Simulasi,” Universitas Negeri Semarang