Analisis Perawatan pada Unit Dump Truck FMX 440 Kapasitas 30 Ton dengan Metode Reliability Centered Maintenance (RCM) Analysis of Maintenance for FMX 440 30-Ton Dump Truck Using Reliability-Centered Maintenance (RCM) Method

Main Article Content

Abstract

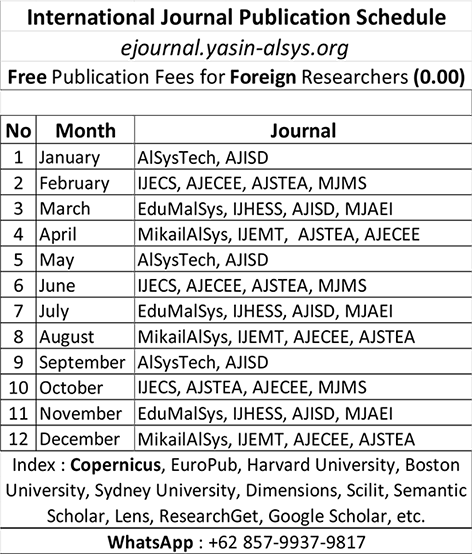

One of the coal mining activities is to move coal from pit to rom using transport equipment, namely dump trucks. In the case study in the field, the dump truck used is FMX 440 with a capacity of 30 tonnes which operates for 18 hours/day. The obstacles or problems encountered during operations include damage and disruption to the dump truck unit system, which can interfere with the mining process and result in a reduction in the amount of coal production targeted by the landowner. Therefore, other methods are needed so that maintenance can be planned and carried out properly. This research aims to find critical components, and maintenance intervals on dump trucks. This research uses the reliability centreed maintenance (RCM) method. The results obtained are critical components, MTBF and MTTR values are cooling system 5,011.96 hours and 1.44 hours, transmission (T / M) system 14,446.24 hours and 2.75 hours, hydraulic oil hose and piping 22,326 hours and 10.54 hours, and air piping and hose 17,541.86 hours and 4.86 hours. From the calculation of the reliability value of critical components, the maintenance time interval for each component is obtained, namely the cooling system is carried out maintenance after 138 operating days, the transmission (T / M) system is carried out maintenance after 416 operating days, hyd. oil hose & piping is carried out maintenance after 638 operating days, and air piping & hose after 500 operating days.

Downloads

Article Details

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

References

Dzaki Kurniawan, A., Sudijono Kromodihardjo, I., & Jurusan Teknik Mesin, Ms. (2016). Penerapan Metode RCM Pada Perawatan Hard Capsule Machine A di PT. Kapsulindo Nusantara.

Ebeling, C. E. (1997). an introduction to reliability and maintainability engineering.

Fathurohman, F., & Triyono, S. (2020a). RCM (Reliability Centered Maintenance): The Implementation In Preventive Maintenance (Case Study In An Expedition Company). EKOMABIS: Jurnal Ekonomi Manajemen Bisnis, 1(02), 197–212. https://doi.org/10.37366/ekomabis.v1i02.29

Friederich, M. C., & van Leeuwen, T. (2017). A review of the history of coal exploration, discovery and production in Indonesia: The interplay of legal framework, coal geology and exploration strategy. International Journal of Coal Geology, 178, 56–73. https://doi.org/10.1016/J.COAL.2017.04.007

Hyva. (2018). Operation And Maintenance Manual. www.hyva.com

Maarif, M. A. (2020). Manajemen Perawatan Truk Jenis Mitsubishi Dengan Pendekatan Metode Realibility Centered Maintenance (RCM) Study Kasus Di Cv. Barokah Djaya. 3(1), 41–46.

Morad, A. M., Pourgol-Mohammad, M., & Sattarvand, J. (2014). Application of reliability-centered maintenance for productivity improvement of open pit mining equipment: Case study of Sungun Copper Mine. Journal of Central South University, 21(6), 2372–2382. https://doi.org/10.1007/s11771-014-2190-2

Muhamat Rizal Abidin, Said Salim Dahda, & Deny Andesta. (2021). Perencanaan Penjadwalan Perawatan Mesin Wheel Loaderdengan Pendekatan Reliability Centered Maintenance di PT. Swadaya Graha. JUSTI (Jurnal Sistem Dan Teknik Industri).

Plant People Development. (2009). Pengetahuan Mesin Plant People Development PT SaptaIndra Sejati.

Plant People Development. (2013). Basic Engine BMC Plant People Development PT SaptaIndra Sejati.

Plant People Development. (2019). Product Knowledge Volvo FM Versi 4 Mechanic Development PT SaptaIndra Sejati.

Sandy Dwiseputra Pandi, Hadi Santosa, & Julius Mulyono. (2014). Perancangan Preventive Maintenance Pada Mesin Corrugating Dan Mesin Flexo di PT. Surindo Teguh Gemilang.

volvo. (2016). Cooling system.

volvo. (2018a). Lubricating and oil system.

volvo. (2018b). VOLVO D13 ENGINE