Implementasi Metode Reliability Centered Maintenance untuk Menunjang Ketersediaan Suku Cadang Unit Prime Mover Truck Tipe 550 Horse Power Implementation of Reliability-Centered Maintenance Method to Support the Availability of Spare Parts for 550 Horsepower Prime Mover Trucks

Main Article Content

Abstract

One of mining materials transport units is a 550 horse power prime mover truck. The prime mover truck functions as the main power source of trailer unit. This research was motivated by unexpected failures of 550 horsepower prime mover truck which operating on extreme mining environments, and unreachable component lifetime also delays of part supply, which contributed to increased downtime. The research purposes are to improve and develop the best maintenance system by identifying critical components, determining reliability values, determine maintenance intervals, and ensuring spare parts availability. The research was conducted using the Reliability Centered Maintenance (RCM) method, with independent variables are failure frequency data and failure duration data. The results identified five critical components, air piping and hose, fast fuel filler, radiator components, radiator hose, and wheel stud and nut. Maintenance intervals were determined when the reliability value approached 0.6, with the air piping and hose component reaching 1750 hours of operation or every 97 days, the fast fuel filler component reaching 1,250 hours or every 69 days, the radiator and reservoir tank component reaching 2250 hours or every 125 days, the radiator hose and line component reaching 2750 hours or every 152 days, and the wheel stud and nut component of 3000 hours or every 166 days.

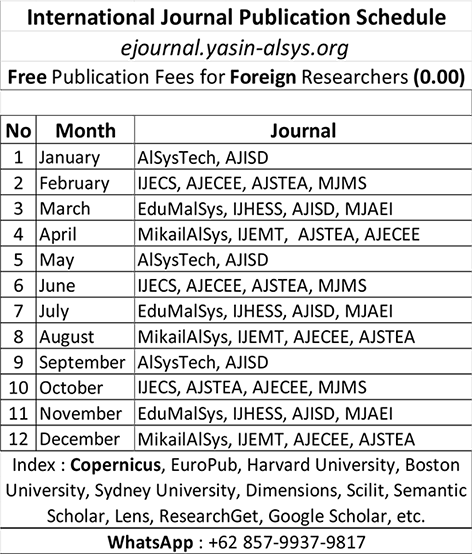

Citation Metrics:

Downloads

Article Details

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

References

Aufar, A. N., Kusmaningrum, & Prassetiyo, H. (2014). Usulan Kebijakan Perawatan Area Produksi Trim Chassis Dengan Menggunakan Metode Reliability Centered Maintenance (Studi Kasus : PT. Nissan Motor Indonesia). Jurnal Online Institut Teknologi Nasional, 02(04), 25–36.

Burhannudin, M., & Ansori, M. (2022). Implementasi Reliability Centered Maintenance Pada Excavator PC-800. 5, 143–150.

Ferdiansah, S. J. 2022. Analisis Keandalan dan Perawatan Mesin Labeling K810D84 dan Packaging Tahun 2023 Sampai 2025 dengan Metode Reliability Centered Maintenance (RCM). Skripsi, Tidak Dipublikasikan. Malang: Politeknik Negeri Malang.

Firmansyah, D. A. 2023 Analisis Perawatan Ketel Uap Pipa Air Kapasitas 80 Ton/Jam Menggunakan Metode Reliability Centered Maintenance (RCM). Skripsi, Tidak Di Tidak Dipublikasikan. Malang: Politeknik Negeri Malang.

Kurniawan, D. 2023. Penerapan Sistem Perawatan Articulated Dump Truck Komatsu HM400-3R Menggunakan Metode Reliability Centered Maintenance (RCM) Sebagai Dasar Kebijakan Perawatan Yang Optimal. Skripsi, Tidak Di Tidak Dipublikasikan. Malang: Politeknik Negeri Malang.

Mahardika, A. A. C. 2021. Analisis Perencanaan Perawatan Terhadap Mesin Klin Dryer Dengan Metode Reliability Centered Maintenance (RCM). Skripsi, Tidak Di Tidak Dipublikasikan. Malang: Politeknik Negeri Malang.

Moniri-Morad, Amin & Pourgol, Mohammad & Sattarvand, Javad. (2013). Reliability-Centered Maintenance for Off-Highway Truck: Case Study of Sungun Copper Mine Operation Equipment. ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE). 15. 10.1115/IMECE2013-66355.

Nugroho, R. D. 2022. Analisis Sistem Perawatan Ketel Uap Pipa Api 3 Phase Type SIB 5000 Menggunakan Metode Reliability Centered Maintenance (RCM). Skripsi, Tidak Dipublikasikan. Malang: Politeknik Negeri Malang.

Nur Fadilah Fatma, Henri Ponda, R. A. K. (2018). Analisis Preventive Maintenance Dengan Metode Menghitung Mean Time Between Failure (MTBF) Dan Mean Time To Repair (MTTR). 17, 87–94.

Nurchayo, R., Sarmita, W., Dachyar, M., & Edison. (2017). Analisis Keandalan Komponen Sistem Proses Pendingin Sekunder Reaktor. Seminar Keselamatan Nuklir, 113–119.

Pranoto, H. (2015). Reliability Centered Maintenance. Mitra Wacana Media.

Pranowo, I. D. (2019). Sistem dan Manajemen Pemeliharaan (Maintenance: System and Management).

PT. Saptaindra Sejati. (2013). Buku Informasi Product Knowledge Volvo FH (4). Diperoleh dari Tim Plant People Development Departemen Hauling.

PT. Saptaindra Sejati. (2013). Buku Informasi Product Knowledge Volvo FH (2). Diperoleh dari Tim Plant People Development Departemen Hauling.

PT. Saptaindra Sejati. (2013). Product Training Volvo FH (4). Diperoleh dari Tim Plant People Development Departemen Hauling.

Putra, E. L. R. (2011). Reliability Centered Maintenance. In E. L. Rusma Putra (Ed.), Marine Technology and Engineering (2011th ed., Vol. 2). https://doi.org/10.31399/asm.hb.v11a.a0006817

Syahabuddin, A. (2019). Analisis Perawatan Mesin Bubut CY-L1640G Dengan Metode Reliability Centered Maintenance (RCM) Di PT. Polymindo Permata. JITMI (Jurnal Ilmiah Teknik Dan Manajemen Industri), 2(1), 27. https://doi.org/10.32493/jitmi.v2i1.y2019.p27-36

Syahruddin. (2012). Analisis Sistem Perawatan Mesin Menggunakan Metode Reliability Centered Maintenance (RCM) Sebagai Dasar Kebijakan Perawatan yang Optimal di PLTD “X.” Jurnal Tekhologi Terpadu, 1(7), 42–49.

Wibowo, T. J., Hidayatullah, T. S., & Nalhadi, A. (2021). Analisa Perawatan pada Mesin Bubut dengan Pendekatan Reliability Centered Maintenance (RCM). Jurnal Rekayasa Industri (Jri), 3(2), 110–120. https://doi.org/10.37631/jri.v3i2.485