Effect of Particle Size and Fiber Loading on Some Properties of Sugarcane Bagasse Reinforced Unsaturated Polyester Composites

Digital Object Identifier:

10.58578/kijst.v1i1.3718

Digital Object Identifier:

10.58578/kijst.v1i1.3718

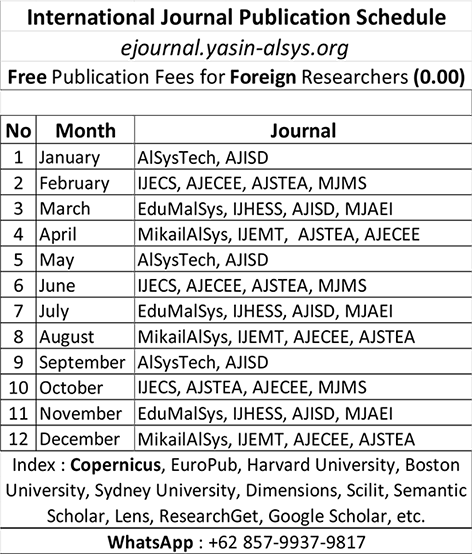

Please do not hesitate to contact us if you would like to obtain more information about the submission process or if you have further questions.

Abstract

In recent times, the use of sugarcane bagasse as reinforcement in plastic composites has been receiving greater scientific attention due to its abundance, light weight and good mechanical properties. This research has investigated the mechanical properties of the composite by hardness strength, impact strength, chemical resistant test, and water absorption test with different particle size and loading of sugarcane bagasse (SCB) as reinforcement in unsaturated polyester resin (UPR) composite. Bagasse fiber was treated with sodium hydroxide (10%), potassium permanganate (5%), hydrogen peroxide (5%) to enhance better adhesion between the fiber and the matrix. Sugarcane bagasse reinforced unsaturated polyester resin composite was prepared using the compression molding technique, the mold was undergoing a curing process for 5 minutes with 1300 c and 2.5Mpa of pressure. The result of the mechanical properties were eval_uated, the mechanical properties (flexural strength, hardness strength) increases with increase in bagasse content while the impact strength increase and then decreases, the maximum mechanical properties was obtained from the composite made of 400µ and 25 wt% fiber loading compared with the control sample. The improvement in the mechanical properties is attributed to the extent of good interaction between the fiber and the matrix. The composite show increase in water absorption with increasing fiber loading and increasing number of days up to when the samples reaches their saturation when no water absorption was observed, 25wt% of 710µ has the highest absorption and this is due to its bigger particle size and fiber loading. The mechanical and physical properties shows that the composite has potential applications in structural materials such as particle board, fiber board, library shelf’s, partitioning panels, ceiling boards.

Citation Metrics:

Downloads

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

References

Ali. B, Jamila, (2016). studies of physical and mechanical properties of unsaturated polyester resin hybrid composites reinforced with jute fiber and maize cob particles. A dissertation submitted to the school of postgraduate studies, Ahmadu Bello university zaria.

Arrakhiz F.Z., Malha M. Bouhfid R., Benmoussa K., Qaiss A.(2013). Tensile, flexural and torsional properties of chemically treated alfa, coir and bagasse reinforced polypropylene, Composites: Part B 47, P35 – 41.

Autar, K.K. (2006). Mechanics of Composite Materials, Second Edition. Mechanical engineering. V. 29.

Bisht, N. and Gope, P.C. (2015). Mechanical Properties of Rice Husk Flour Reinforced Epoxy Bio-Composite. International Journal of Engineering Research and Applications. Vol 5, Pp.123-128.

Cao, Y., Shibata, S., & Fukumoto, I. (2006). Mechanical properties of biodegradable composites reinforced with bagasse fibre before and after alkali treatments. Composites Part A: Applied Science and Manufacturing, 37, 423–429. doi:10.1016/j. compositesa.2005.05.045.

Chandramohan, A.D. and Marimuthu, B.K. (2011). Tensile and Hardness test on Natural Fiber Reinforced Polymer Composite Material. International Journal of advanced engineering Science and Technologies. Vol. 6, issue 1, pp. 97-104.

Chioma, M.I. Babatunde, B. Reginald, U. Jennifer, N.N. (2014). Comparison of the mechanical properties of charcoal unsaturated polyester matrix composite and snail shell unsaturated polyester matrix composite. International journal of scientific & engineering research, volume 5, pp 208-213

Farag M M. Quantitative methods of materials substituion: Application to automotive components. Mater Des 2008;29: 374-380

Kabir. M.M, Wang.H, Aravitha. T, Cardona. F, and Lau. K.T, (2011). Effect of natural fiber surface on composites properties book of proceedings pp 94-99.

Nabi Sahib D and Jog J P 1999 Adv. Polym. Technol. 18 351

Omole, J. T., & Dauda, B. (2016). Physical and mechanical properties of chemically treated bagasse fibre for use as filler in unsaturated polyester composite. International Journal of Composite Materials, 6, 48–54

Rangaswamy, H., Harsha, H.M., Chandrashekarappa, M.P.G., Pimenov, D.Y., Giasin, K. and Wojciechowski, S. (2021). Experimental Investigation and Optimization of Compression moulding Parameters for MWCNT/Glass/Kevlar/Epoxy Composites on Mechanical and Tribological Properties. Journal of Materials Research and Technology (Jmr&t). Vol. 15: 327–341.

Rowell, R.M., 1997, Chemical modification of agro-resources for property enhancement”, Paper and Composites from Agro-based Resources,CRC Press. p. 351-375.

Tahir , Paridah MD, Amel B. Ahmed,Syeed O. A. Saiful A and Zakiah A,(2011). Review of

bast fibre retting‖Bioresourses 6(4), 5260-5281.